🛠️ Tooling and Manufacturing: Bridging Design and Production with Precision

At StrucToolSolutions, we don’t just design—we deliver. Our Tooling and Manufacturing services ensure that your parts move seamlessly from digital models to physical reality. Whether it’s additive or subtractive manufacturing, custom jigs and fixtures, or CNC tooling strategy, we engineer every step for efficiency, accuracy, and repeatability.

🧩 Additive & Subtractive Manufacturing

We support both 3D printing (additive) and machining (subtractive) workflows, selecting the right process based on geometry, material, and performance needs.

Additive Manufacturing: Ideal for complex geometries, lightweight structures, and rapid prototyping. We design for FDM, SLA, SLS, and metal AM.

Subtractive Manufacturing: CNC milling, turning, and EDM for high-precision parts in metals and plastics. We optimize for tool paths, tolerances, and surface finish.

Our hybrid approach ensures that each part is manufactured efficiently and accurately, using the best-fit technology.

🧰 Jigs & Fixture Design

Custom jigs and fixtures are essential for repeatable, accurate, and safe manufacturing. We design:

Assembly fixtures for multi-part alignment

Inspection jigs for quality control

Workholding solutions for CNC and manual setups

Our designs are tailored to your production environment, reducing setup time and improving throughput.

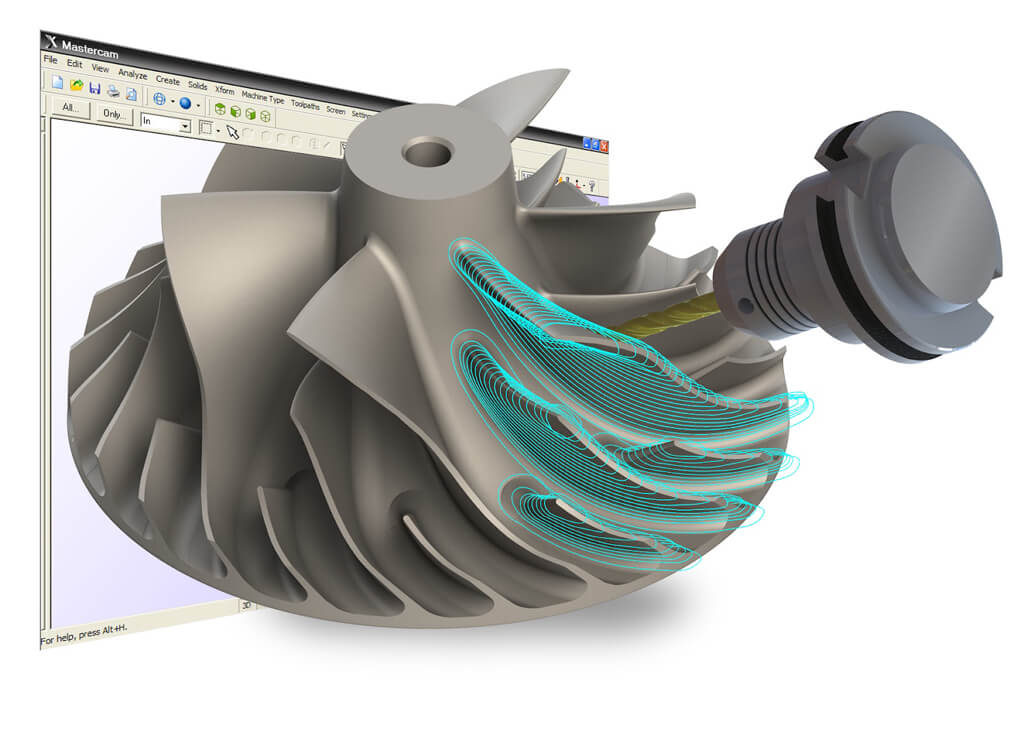

🖥️ CAM: From CAD to Machine

Using Computer-Aided Manufacturing (CAM), we generate tool paths and machining strategies directly from your CAD models.

2.5D and 3D milling operations

Multi-axis toolpath generation

Simulation of cutting forces and tool engagement

We ensure that every CAM file is optimized for speed, accuracy, and tool longevity, reducing trial-and-error on the shop floor.

🔩 CNC Cutting Tools: Selection & Procurement

Choosing the right cutting tools is critical for performance and cost. We help you:

Select tools based on material, geometry, and machine capabilities

Optimize tool life and surface finish

Source high-quality endmills, drills, inserts, and holders from trusted suppliers

Whether you’re machining aluminum, titanium, or composites, we match your needs with the right tooling strategy—and help you purchase efficiently.

🚀 Why It Matters

Tooling and manufacturing is where engineering meets execution. Poor choices here lead to delays, defects, and wasted resources. At StrucToolSolutions, we combine design intelligence, manufacturing experience, and digital workflows to ensure your parts are ready for production—fast, accurate, and cost-effective.